FRESHINDEX NEWS

LET’S TALK ABOUT: COMING FROM A VIRTUAL TO A REAL WORLD

Long time, no see – since our last Blogpost in December 2018 a lot has happened. Following up on our first Milestone Meeting with our project sponsor in November 2018, it was time for taking a closer look on what is going to be at the heart of the second half of the FreshIndex project. While 2018 was all about gathering data, one of the major challenges for the ongoing year will be the transfer from virtual space to the real world.

Wrap-up and Status Quo

The first phase of the FreshIndex research project focused on food modelling and simulation models to predict freshness of packed meat. Predictions were based on temperature profiles along the supply chain and hygiene factors on production time. At the same time, track and trace related questions were focusing on how to access or generate all the required data. For all those subdomains the consortium found possible solutions and verified them with software spikes and/or test series and – in the end – proved that FreshIndex or its vision is feasible in principle. A major challenge for the next phase of the project will be to bring all the created pieces together and prove that dependencies between them can be handled efficiently. Our defined goal is to verify the system to be created within a 2-month field test with real world data which will not only verify our models and assumptions but will additionally identify possible gaps in automatically providing the FreshIndex throughout the food supply chain. Here, a number of IT components are required for the next phases – e.g. the Virtual Supply Chain which was programmed and designed during 2018.

The Virtual Supply Chain (VSC)

The VSC a configurable simulator for food supply chains. It covers producers, distribution centres, chain stores and transports between those supply chain participants. For the FreshIndex project, the VSC has three main goals. Firstly, the VSC supports uniquely identifiable articles and therefore decrease complexity. Thus, able to start simple and consider “real world supply chains” progressively. Secondly the VSC is able to generate a huge amount of test data. With this data it is possible to evaluate scalability and performance characteristics of the system architecture. And thirdly, the VSC supports exceptional situations like defect sensors or high temperature which allows to also have a look at “non-happy” use cases.

However, in order to come from a purely virtual supply chain to the real world, real world data need to be included in the equation. Here, a close collaboration between arconsis, who responsible for the software side of the FreshIndex, and the working group “Cold Chain Management” at the University of Bonn, who is responsible for the collection and analysis of microbiological data, is crucial.

Find out more about out the FreshIndex IT Components here >>>

FRESHINDEX COMMUNITY

Engage in the FreshIndex Field Test

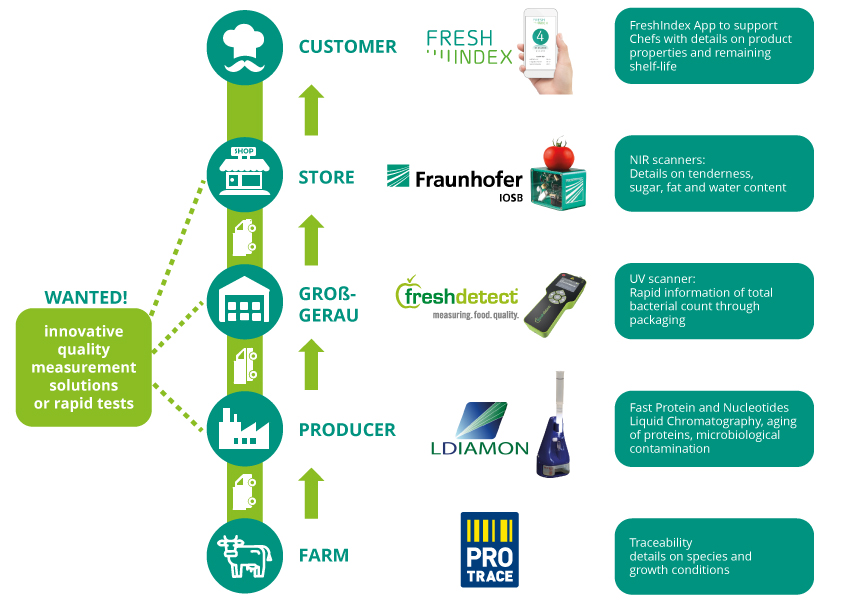

You are a service provider offering innovative quality measurement solutions or rapid tests for food safety and data quality?

If so, you are very welcome to be part of our field trial in August 2019. We are looking for companies to assure and asses quality of our data and the product along the supply chain. If you are interested in showcasing your solution to Metro as part of our field trial, please contact the FreshIndex team.

MEET THE PROJECT PARTNERS: University of Bonn

The working group ‘Cold Chain Management’ is part of the Institute of Animal Science at the University of Bonn. The group was founded 2003 by Prof. Dr. Judith Kreyenschmidt. The research group focuses on the optimization of food quality and safety of perishable products. One major research field is the reduction of food waste by implementing new technologies for enhancing the sustainability and resource efficiency in the food production sector. Besides the development of active and intelligent packaging solutions to prolong shelf life of perishable food, the group has long experience in the field food spoilage- and shelf life modeling.

The working group is responsible in the FreshIndex project for the characterization of the spoilage process of different meat products. This includes investigations to describe the effect of the most important influence factors on the spoilage process. The group also supports the development of the model to predict the freshness loss of the investigated products.

MEET THE FACES BEHIND

|

Prof. Dr. Judith Kreyenschmidt has a Professorship at the Geisenheim University and she is the head of the cold chain management group at the University of Bonn. She has more than 15 years of research experience in the areas of predictive microbiology, meat science, temperature monitoring, active and intelligent packaging. She has been involved in several publicly funded national and international research projects and in several industry projects. In 2011, her working group was awarded by the European Retail Institute for its interdisciplinary research and innovative teaching method. |

|

Antonia Albrecht finished her studies in Biology with a diploma in the year 2008 and started at the working group the same year. She gained experience in the field of microbial modeling, shelf life assessment and application of novel technologies to improve cold chain management. During her PhD she investigated animal specific influence factors on the quality and shelf life of fresh pork and poultry meat. Her research interest is in the field predictive microbiology, sustainable packaging solutions, dynamic shelf life application, intelligent packaging with TTIs. She focuses mainly on chilled fresh products, such as meat, under different packaging conditions. |

|

Dr. Stephanie Krieger-Güss has graduated in Food Science in the year 2002 at the University of Bonn. The topic of her following phd-thesis, which she wrote at the Institute of Food and Resource Economics was the cost and benefits of quality systems in the agri-food chain. She joined the company Tetra Pak as a TQM manager and quality assurance manager. Afterward, she worked as quality manager for the Coca-Cola AG. After paining practical experience in the food sector, her way led back to science in November 2018. Since the end of last year, she is participating in the project FreshIndex. |

|

Martin Hebel graduated in Food Technology in 2013 at the University of Bonn. He gained practical experience during his work in the quality assurance teams of Audrey Cake GmbH and Kronenbrot KG. During his employment at QHP Life Science GmbH, he coordinated a joint research project focusing on online diagnostics of spontaneously fermented wine. In 2015, he returned to the University of Bonn to focus on his PhD. His research interests are in rapid detection methods for analysing quality relevant parameters. He investigates the applicability of biosensor-based systems for food investigations. |